Consider, for instance:For instance, if the tolerances of a product are either too lenient or inconsistent with the tolerances of the parts with which it is intended to be assembled, it may not be possible to put the product together as it was intended.Because of this, there is a possibility that additional work will be required, or even, in the worst case scenario, the finished product won't even be usable.The tolerances of the parts with which the product is meant to be assembled ought to be the same as the tolerances of the parts used in the product itself.In addition, some definitions of some of the callouts that are utilized most frequently have been provided here for your convenience.In addition to this, we are going to talk about the Geometric Dimensioning and Tolerancing (GDT) standard, which is the standard that is used as the benchmark for part tolerances in the industry. GDT stands for the Geometric Dimensioning and Tolerancing Association.The Geometric Dimensioning and Tolerancing Association is what GDT stands for.

Tolerances for the machining are expected to be within a range of +/- 0.005 millimeters (0.In the event that you intend to machine a bracket with a width of 1 (25.4 mm), a length of between 0.273 and 25.25 (6.35 mm) in one of the legs, then the diameter of the bracket should be between 0 and 1.25.This is because the machining process for the bracket will be affected in a certain way depending on the width of the bracket itself.On the other hand, I think that captures the essence of it pretty well..

2,000 millimeters, give or take 0.Metric values are also acceptable.Please check to see that the dimensions and tolerances, which are shown with three digits, are adhered to, and avoid adding any additional digits that are either zero or one. Both sets of numbers are displayed with three digits.Because of this, there won't be any room for confusion as a result of what's happened.When machining tolerances, it is absolutely necessary to keep certain considerations in mind at all times.In relation to the amount of Roughness that can be discovered on the Surface

When determining the tolerances for a specific part, several dimensions are taken into consideration. These dimensions include the length of the part, its width, and the size of any holes that the part may contain.We also take into account other characteristics, such as the roughness of the surface, in addition to this.When it comes to standard products, the surface roughness should be equivalent to 63 in for flat and vertical surfaces, and it should be equivalent to 125 in or better when it comes to curved surfaces.This is true for surfaces that are horizontal as well as those that are vertical.However, when it comes to decorative surfaces on CNC turning china metal parts, the appearance can often be improved by using a light blast. This is because light blasting is less abrasive than other types of blasting.This finish is suitable for the vast majority of applications and can be used successfully in all of them.We ask that you specify in your design exactly where on the surface you would like more of a smooth finish, and we promise that we will do everything that is physically possible to meet your requirements. If you comply with this request, we will do everything that is physically possible to meet your requirements.measurements pertaining to geometry, as well as degrees of permissible error

As a final point to take into account, kindly keep in mind that we are able to tolerate GDT tolerances. This is an important consideration to take into account.Earlier, some thought was put into addressing this problem.Because of this, a higher level of quality control is achieved, one that takes into account the relationships between the numerous part features and the shape and fit qualifiers.This is the outcome of it.Because of this, we were able to ascertain the correct location of the hole.As a consequence of this, we were able to calculate the exact measurements of the hole.Which one it will be can be determined by the qualifier.

Consider, for instance:For instance, if the tolerances of a product are either too lenient or inconsistent with the tolerances of the parts with which it is intended to be assembled, it may not be possible to put the product together as it was intended.Because of this, there is a possibility that additional work will be required, or even, in the worst case scenario, the finished product won't even be usable.The tolerances of the parts with which the product is meant to be assembled ought to 5 Axis CNC Machining Services be the same as the tolerances of the parts used in the product itself.In addition, some definitions of some of the callouts that are utilized most frequently have been provided here for your convenience.In addition to this, we are going to talk about the Geometric Dimensioning and Tolerancing (GDT) standard, which is the standard that is used as the benchmark for part tolerances in the industry. GDT stands for the Geometric Dimensioning and Tolerancing Association.The Geometric Dimensioning and Tolerancing Association is what GDT stands for.

Tolerances for the machining are expected to be within a range of +/- 0.005 millimeters (0.In the event that you intend to machine a bracket with a width of 1 (25.4 mm), a length of between 0.273 and 25.25 (6.35 mm) in one of the legs, then the diameter of the bracket should be between 0 and 1.25.This is because the machining process for the bracket will be affected in a certain way depending on the width of the bracket itself.On the other hand, I think that captures the essence of it pretty well.

2,000 millimeters, give or take 0.Metric values are also acceptable.Please check to see that the dimensions and tolerances, which are shown with three digits, are adhered to, and avoid adding any additional digits that are either zero or one. Both sets of numbers are displayed with three digits.Because of this, there won't be any room for confusion as a result of what's happened.When machining tolerances, it is absolutely necessary to keep certain considerations in mind at all times.In relation to the amount of Roughness that can be discovered on the Surface

When determining the tolerances for a specific part, several dimensions are taken into consideration. These dimensions include the length of the part, its width, and the size of any holes that the part may contain.We also take into account other characteristics, such as the roughness of the surface, in addition to this.When it comes to standard products, the surface roughness should be equivalent to 63 in for flat and vertical surfaces, and it should be equivalent to 125 in or better when it comes to curved surfaces.This is true for surfaces that are horizontal as well as those that are vertical.However, when it comes to decorative surfaces on metal parts, the appearance can often be improved by using a light blast. This is because light blasting is less abrasive than other types of blasting.This finish is suitable for the vast majority of applications and can be used successfully in all of them.We ask that you specify in your design exactly where on the surface you would like more of a smooth finish, and we promise that we will do everything that is physically possible to meet your requirements. If you comply with this request, we will do everything that is physically possible to meet your requirements.measurements pertaining to geometry, as well as degrees of permissible error

As a final point to take into account, kindly keep in mind that we are able to tolerate GDT tolerances. This is an important consideration to take into account.Earlier, some thought was put into addressing this problem.Because of this, a higher level of quality control is achieved, one that takes into account the relationships between the numerous part features and the shape and fit qualifiers.This is the outcome of it.Because of this, we were able to ascertain the correct location of the hole.As a consequence of this, we were able to calculate the exact measurements of the hole.Which one it will be can be determined by the qualifier.

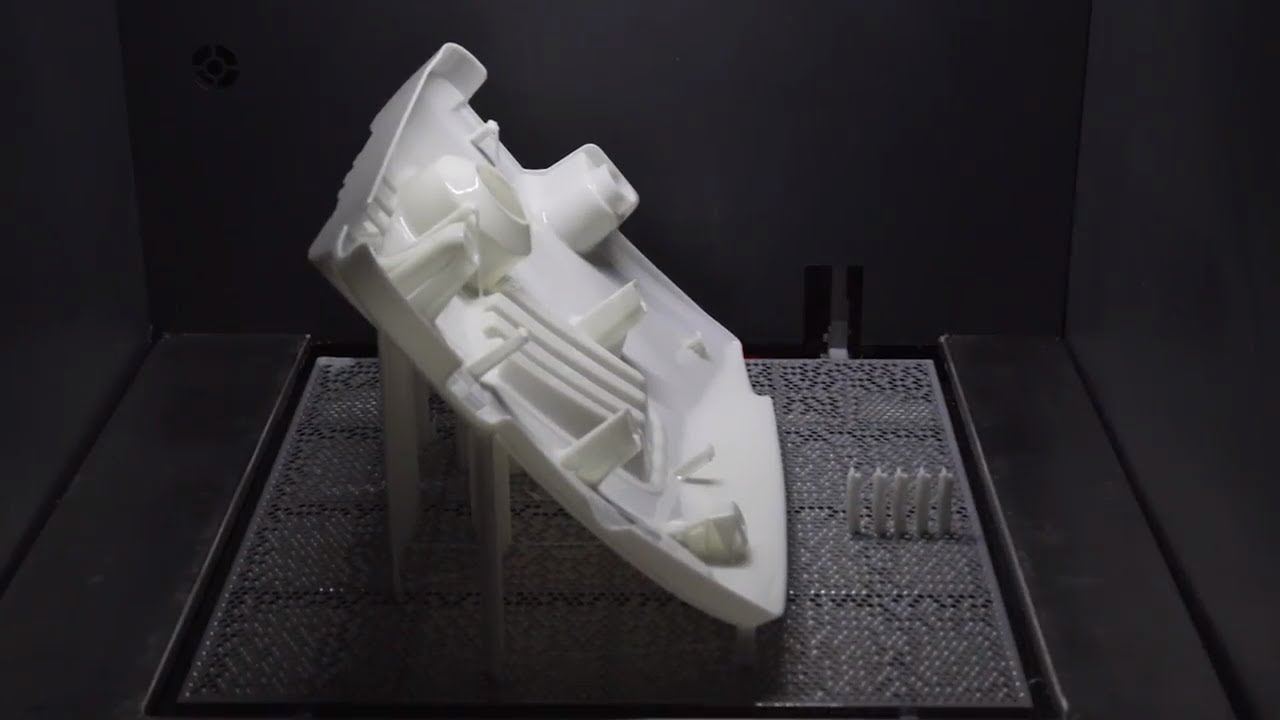

Flatness: Milled surfaces are typically very flat; however, some warping may occur after the part has been removed Plastic 3D Printing from the machine as a result of internal material stress or clamping forces that occurred during the machining process. This warping may occur as a result of the internal material stress or clamping forces that occurred during the machining process. This warping may have been caused by internal material stress or clamping forces that were present during the machining process. Flatness can be defined as the absence of significant differences in surface height between adjacent milled surfaces. Flatness is a desirable property in many applications. The absence of significant elevation changes across a surface is the defining characteristic of flatness. This is kept under control by the GDT flatness tolerance, which establishes two parallel planes that the milled surface has to lie within in order for it to be considered acceptable. If the milled surface does not lie within these planes, then it is not acceptable. This is due to the fact that a lathe is required to perform turning. This is because of the necessity of utilizing a lathe in order to carry out turning. If, on the other hand, we assume that the hole in the example bracket has a tolerance of +/- 0. 255 millimeters in a unidirectional direction, then the situation is slightly different. Cylindricity is defined as the condition of having two cylinders that are arranged in such a way that they are concentric to one another.

This property, which is also observed in liquids, is referred to as concentricity and can be found in both solids and liquids. This can be achieved by making certain that the hole is centered exactly where it should be. It is possible to accomplish this objective if you take the necessary precautions to ensure that the hole is properly aligned with a reference point. It is imperative that this alignment be carried out with the highest level of accuracy. In addition to this, it can be utilized to control the perpendicularity of the turned shoulder in relation to the adjacent diameter or to the axis that travels through the middle of the component. This can be accomplished by turning the turned shoulder in the opposite direction of the adjacent diameter. To accomplish this, turn the turned shoulder in the opposite direction of the adjacent diameter. This will allow you to achieve the desired result. Not only do we need 2D drawings, but also 3DCAD models, so that we can figure out what the GDT tolerances are going to be. It could also mean that in addition to our standard cutting tool set, we use machining processes such as wire EDM, EDM, grinding, and boring in order to meet the quality standards that you have established for your part. These standards have been established by you. In accordance with the requirements that are outlined in the specifications, we will perform a comprehensive inspection on each and every one of your parts. In addition to that, we will be able to provide you with quality inspection reports, a first article inspection CNC drill machining (also referred to as FAI), material certification, and a wide variety of other services that are associated with this topic. In the event that you have any inquiries or concerns at any time, please do not be reluctant to get in touch with us.